-

Phone

86-510-86653369

-

Address

No. 3388, Zhencheng Road, Huangtu Town, Jiangyin City, Wuxi, Jiangsu, China

-

E-mail

PLC Automatic Condenser Rubber Ball Tube Cleaning Equipment

China PLC Automatic Condenser Rubber Ball Tube Cleaning Equipment, Find details about China Water Treatment System, Water Treatment from PLC Automatic Condenser Rubber Ball Tube Cleaning Equipment - Jiangsu YLD Water Processing Equipment Co., Ltd.

Description

- Model NO.: YL-LN-100

- Usage: Environmental Protection, Chemical Industry, Tube

- Style: Vertical

- Certification: CE

- Material: Carbon Steel/Stainless Steel

- Serve Water: ≥8 L/S

- Ball Catcher Resistance: <0.5m

- Apply: Cleaning Scale and Foulings

- Control Mode: Automatic Cleaning, Manual Time Cleaning

- Transport Package: Plywood Case Into Container

- Origin: Jiangyin, Jiangsu, China

- Type: Conditioner

- Motive Force: Electric power

- Performance: Efficient Filtration

- Item: Condenser Tube Rubber Ball Cleaning Equipment

- Inlet & Outlet Diameter: 4 Inch

- Working Pressure: 1.6MPa

- Power: 200--1000W

- Power Supply: According to Customers′ Require

- Trademark: YLD

- Specification: CE, SGS

- HS Code: 8421219990

Overview

For central air conditioning condenser and evaporator pipe, it is easy to be scaling. The normal daily water treatment should be processed during the summer time cooling water supply period,otherwise, the condenser will run in the high degree hardness water system,inorganic salts dissolved in circulating cooling water system will be crystallized and precipitated out ,scales will be formed on the tubes of condenserand it will reduce heat exchange efficiency. as hard scale increased, energy-consumption will be increased, when the knot hard mass scale is 1mm in thickness,the energy cost will be increased by 6%~10%; as water form scales with dirt, sediment, and rot colonization dirt, also the bacteria, and algae, microbial and its secretion form bio stick mud, it will attach in the pipes of condensation device, seriously it will caused pipeline block.Dirt and mud will effect hot exchange efficiency, higher energy cost will lead to high power voltage, seriously it cause super pressure voltage tilldowntime. Allthese factors affect the normal operation of the heat exchanger.

Ball-type ATCS have ideal applications on steam surface and overhead condensers, large chiller systems, auxiliary heat exchangers, and often are found in the following:

Power Plants (Fossil, Nuclear, Geothermal, Cogeneration)

District Heating and Cooling Plants

Desalinization Plants

Petrochemical and Refining Plants

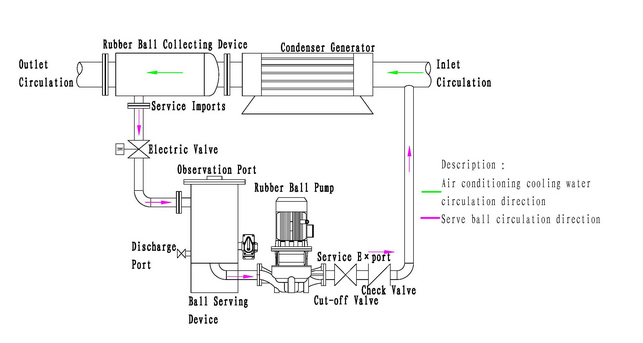

This type of ATCS is applied exclusively to condensers and heat exchangers with water tubeside. The Ball type ATCS functions through the creation of a closed loop within the greater circulating water system. Within this closed loop sponge rubber balls are circulated, which by random selection flow through all tubes on a frequent basis, thereby maintaining optimum tubeside cleanliness.

The system has one or more of each of the six main components listed below and shown in the accompanying illustration.

Ball strainer

Ball recirculation pump

Ball collector vessel

Ball injector

Control panel

Cleaning balls

The cleaning balls are introduced and removed from the system through the ball collector. The collector interior is partitioned by a screen into two areas. When the collector is in the ball collection or retention mode the screen separates the collector inlet and outlet. When the screen is positioned such that the inlet and outlet are no longer separated, the balls are conveyed by the flow to the injection site(s). The balls are injected into the cold leg of the circulating cooling water system serving the condenser or heat exchanger so as to achieve a random distribution within the stream. Because the balls (when deaerated) have nearly the same specific gravity as the cooling water, they follow the same path as the water within which they are suspended.

Ball Collector in the open (recirculation) mode. Both the inlet and outlet of the collector are on the same side of the collector screen.

Ball Collector in the collection (ball capture) mode. The screen has been rotated so as to separate the inlet and outlet of the collector.

When the ball charge is correctly sized, each tube is treated by a ball approximately once every five minutes. When the balls have passed through the tubes and enter the cooling water discharge line they are intercepted by the ball strainer(s). When the balls meet the strainer screen they are driven along the screen surface to the ball extraction port located at the point where the down stream extremity of the screen meets the spool body. The balls are then conveyed by a special pump through the ball collector and once again to the injection site.

|

Name |

Diameter of ball(mm) |

Diameter of ball(mm) |

|

Ordinary rubber ball |

16,17,18,19,20 | 21,22,23,24,25,26,28 |

| Emery rubber ball | 12,14,16,17,18,19,20 | 21,22,23,24,25,26,28 |

| Standard peeling rubber ball | 12,14,16,17,18,19,20 | 21,22,23,24,25,26,28,29 |

Projects:

Our services:

We provide 24 hours online customer service.

Any inquiry about water treatment system, please feel free to contact me for further details!

Contact information:

Mobile phone/ : +86

Official website:

Guarantee period:1 year

After-sale service:800-827-87-226

Related Products

-

Water Purification Water Treatment Water Filter Reverse Osmosis System Equipment

-

Water Pollution Treatment Descaling Filtration Sterilization Water Treatment Equipment

-

Ultra-Filtration Water Treatment Equipment 2000L/H (UF-2000L)

-

Water Filter Cartridge Manufacturing Equipment/ PP fiber filter machine